Link Technologies - LinkSOFT Documentation

Link Technologies - LinkSOFT Documentation  Link Technologies - LinkSOFT Documentation

Link Technologies - LinkSOFT Documentation A kit is a list of inventory items and resources you use to make another item. A kit can include raw materials, purchased or manufactured subassemblies and finished goods and resources such as

machinery and labour. The kit contains everything required to make an item.

If an items status is set to Kit, the Kit Item button on the Product Master is enabled:

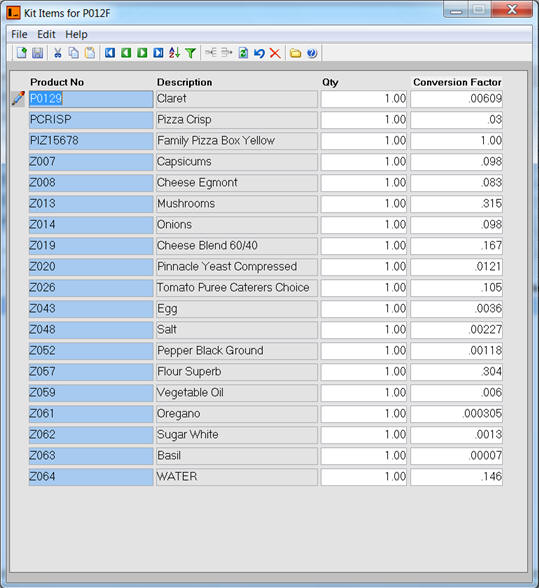

Select the Kit Item button and the following screen appears:

Select the Add New Record icon to insert a new line record.

Double click on Product No. field and select the items to include as part of the kit.

Enter Conversion Factor

|

Fields |

Description |

|

Quantity |

By default this is '1'. |

|

Description |

The amount that will be used to make the

parent item. Note: This factor is also used to calculate the cost of the main item. The system automatically calculates the cost of the main item based on the cost and conversion factor entered for each item in the kit. Total Cost Per Item = Unit Cost of an item * Conversion Factor Parent Item Total Cost = Total Cost of all the items |

Note:

You must create an item as an inventory item (in the Product Master screen)

You cannot use a Non Quantity bearing item in a kit;

you cannot use serial tracked item in a Kit;

Once an item is selected as part of the Kit, the item will not show as part of the search list as you cannot enter the same item twice.

Example: You operate a pizza shop and make Vegetarian Pizza (Product Code: P012F). To make Product Code P012F, you use an ingredient Cheese (Product Code: Z008) and Oil (Product Code: Z059). You need to create product Z008 and Z059 before you can select it as part of the kit for Product P012F.